| In our Technical Center, we cooperate with producers of raw materials for water-borne paints based on test programs tailored individually to client expectations.

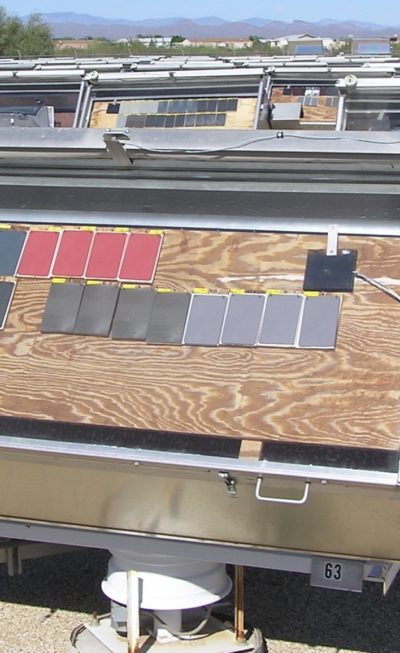

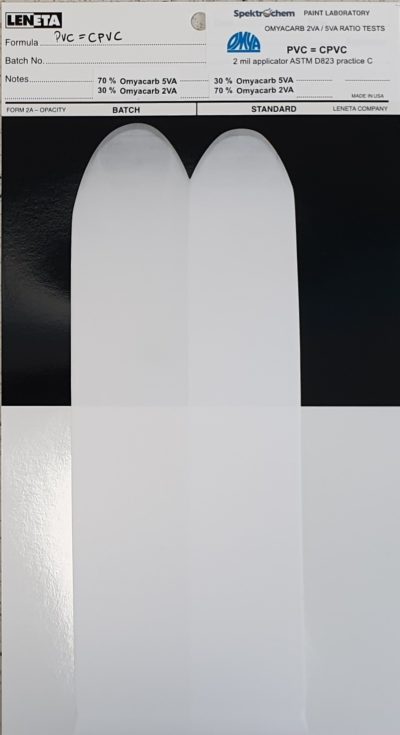

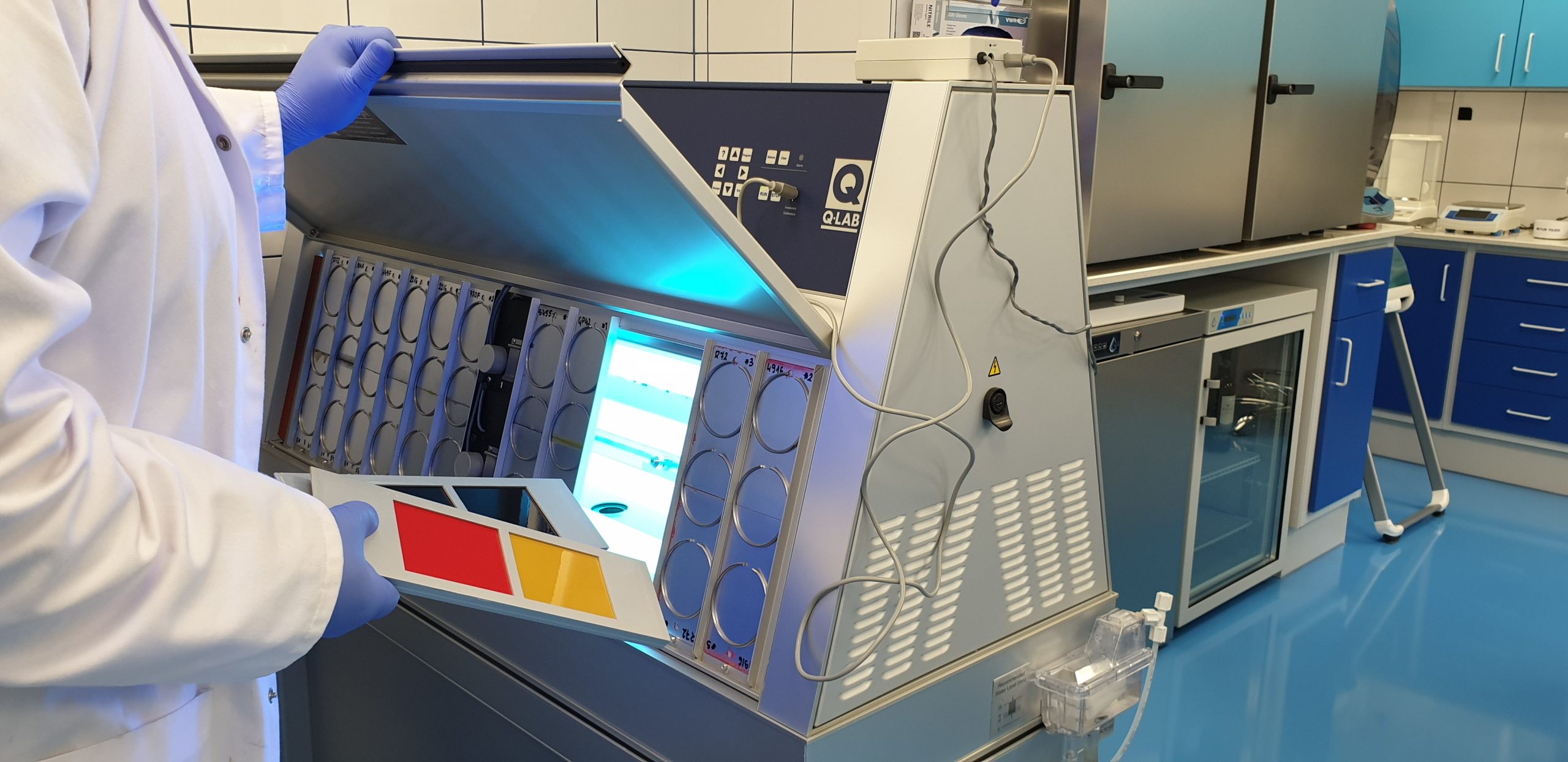

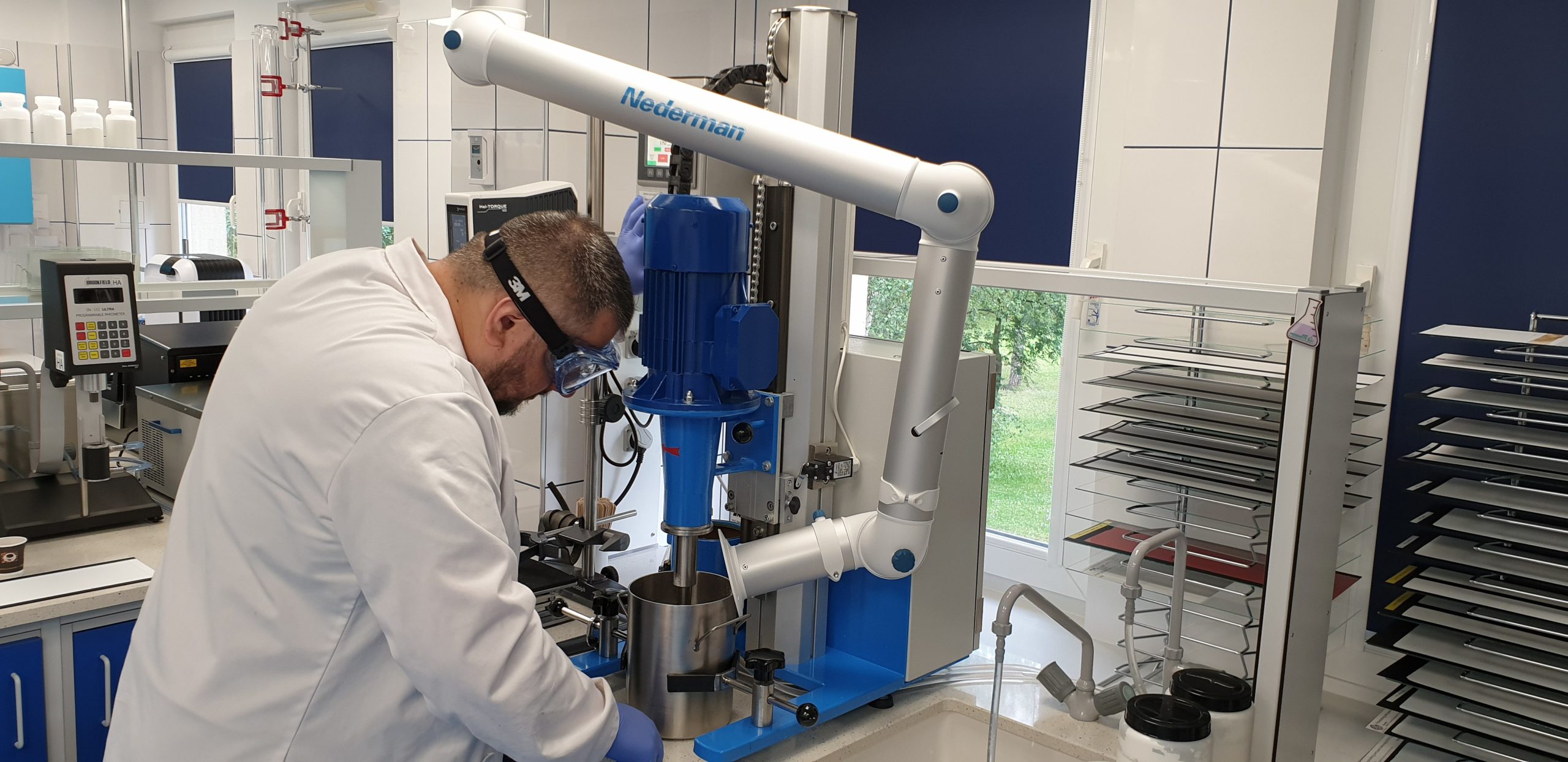

Based on case studies carried out in our laboratory, we develop test reports that are extremely helpful for the TS&D, technical marketing and R&D departments of raw material producers to develop technical materials that accelerate the implementation of raw materials on the global coatings market. Our laboratory specializes in formulating recipes and testing raw materials for water-based architectural, wood and metal paints, in which we test the effectiveness and performance of raw materials in formulations with different pigment volume concentration, based on various binders, additives, fillers, etc., intended for the markets of USA, Canada, North America, Europe and Asia-Pacific (based on locally available raw materials for each region).

We specialize in developing:

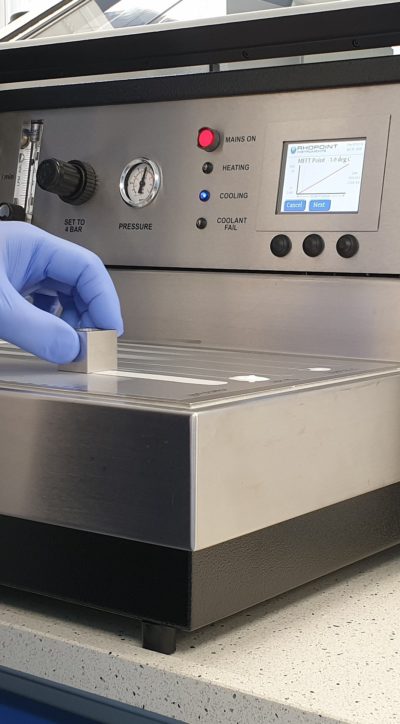

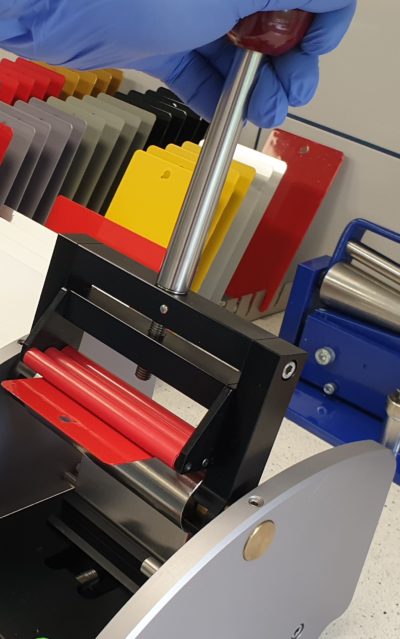

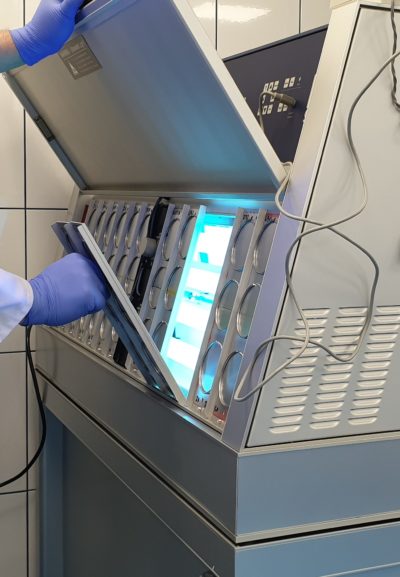

While developing the above, we prepare paints based on raw materials from our raw material library and test samples sent by the customer, we perform tests of liquid paints, their drying processes and dried coatings. We perform tests in accordance with the standards of ASTM, ISO, Federal Test Methods, AATCC, MPI, etc.

At the end of the projects, we present the client with extensive reports, photos from tests, coatings after tests and give the opportunity to visit our laboratory to summarize the test results or we summarize the project by meeting on-line. |

+48 15 822 45 22

+48 15 822 45 22  laboratorium@spektrochem.pl

laboratorium@spektrochem.pl